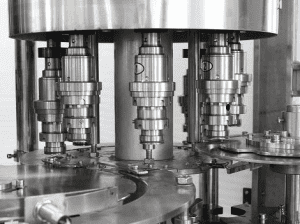

Umshini ozenzakalelayo wokugcwalisa isiphuzo se-carbonated

Buza Manjeumshini wokugcwalisa isiphuzo se-carbonated-Izici

1. Lolu hlobo lomshini wokugcwalisa isiphuzo se-carbonated luhlanganisa ukugeza, ukugcwalisa kanye nemisebenzi ye-rotary capping kuyunithi eyodwa.Kuyimishini yokupakisha uketshezi oluzenzakalelayo ngokugcwele futhi olusebenza kahle kakhulu.

2. umshini wokugcwalisa isiphuzo se-carbonated ufanelekile ukupakisha isiphuzo esiqukethe igesi. Ukusebenza komshini wokugcwalisa isiphuzo se-carbonated kunjengokulandela zonke izingxenye, ngokwesibonelo, i-valve yokugcwalisa, ethintana ngqo nendawo eyenziwe ngensimbi engagqwali noma impahla engenabungozi. Ngakho-ke ihambisana nezidingo zokuthuthwa kwendle Ukudla. Izingxenye zokuvala zenziwe ngenjoloba evikela ukushisa, ukuze kuhlangatshezwane nezidingo zesu labasebenzisi ukuvala inzalo ezingeni lokushisa eliphezulu.

3. Umshini wokugcwalisa isiphuzo se-carbonated Ukusebenzisa isilawuli esihlelekayo ukuze ukwazi ukulawula okuzenzakalelayo ngokugcwele kusukela emabhodleleni angena ekuqedeni ukupakisha, umshini wokugcwalisa isiphuzo se-carbonated Ukusebenzisa i-transducer njengomlawuli wejubane, ukuze umsebenzisi angakwazi ukulawula umshini kalula ukuze uvumelane nezidingo ezahlukene zamandla, Ukwamukela isimiso sokugcwalisa ukucindezela okulinganayo. kanye nama-valve asentwasahlobo amanje ukuze kuqinisekiswe ikhwalithi yesiphuzo, Ukusebenzisa i-coupler magnetic ethuthukisiwe ukulawula i-torque ye-cap-screwing, ukuze kuqinisekiswe ukumboza. izinga.

Ipharamitha yobuchwepheshe

| Imodeli | I-DCGF 16-12-6 | I-DCGF 18-18-6 | I-DCGF 24-24-8 | I-DCGF 32-32-10 | I-DCGF 40-40-12 | I-DCGF 50-50-15 |

| Ukugeza No | 16 | 18 | 24 | 32 | 40 | 50 |

| Ukugcwalisa inombolo | 12 | 18 | 24 | 32 | 40 | 50 |

| I-Capping No | 6 | 6 | 8 | 10 | 12 | 15 |

| Amandla Okukhiqiza(500ml) | 3000BPH | 5000BPH | 8000BPH | 12000 I-BPH | 15000 I-BPH | 18000 I-BPH |

| Faka Umthamo(KW) | 3.5 | 4 | 4.8 | 7.6 | 8.3 | 9.6 |

| Usayizi uwonke | 2450×1800 × 2400 | 2650×1900 × 2400 | 2900×2100 × 2400 | 4100×2400 × 2400 | 4550×2650 × 2400 | 5450×3210 × 2400 |

1. Ukusebenzisa umoya wathumela ukufinyelela futhi ukuhambisa isondo ebhodleleni ngqo exhunywe ubuchwepheshe; Isikulufu esikhanseliwe namaketango okuhambisa, lokhu kwenza ukuthi ushintsho olumise okwebhodlela lube lula.

2. Ukuhanjiswa kwamabhodlela kusebenzisa ubuchwepheshe be-clip bottleneck, uguquko olumise okwebhodlela aludingi ukulungisa izinga lemishini, kwanele ukushintsha okuhlobene nepuleti eligobile, izingxenye zesondo nezenayiloni.

3. Isiqeshana somshini wokuwasha ibhodlela lensimbi engagqwali esiklanywe ngokukhethekile siqinile futhi siqinile, akukho ukuthinta ngendawo yesikulufu yomlomo webhodlela ukuze kugwenywe ukungcoliswa kwesibili.

4. I-cylinder drive valve ukunyakaza kunembile futhi kuthembekile. I-valve yokugcwalisa ephezulu, enembayo ephezulu, egcwalisa ngokushesha futhi enembile. Ifakwe iluphu ye-CIP kanye nezinqubo zokulawula, okokusebenza kulula ukuzihlanza.

5. Ukwehla kwe-Spiraling lapho ibhodlela eliphumayo, guqula isimo sebhodlela asikho isidingo sokulungisa ukuphakama kwamaketanga okuhambisa.

6. Ukusebenzisa isilawuli esihlelekayo njengezikhungo zokulawula; kusetshenziswa i-pressure transmitter, ukulinganisa kwe-electromagnetic ukugcina ibhalansi yendawo ewuketshezi ukuze kuqinisekiswe ukuzinza koketshezi.

7. I-valve yokugcwalisa yokuklama entsha, igesi yokubuyisela kanye noketshezi lokugcwalisa kuhlukene ukuze kuqinisekiswe ukuthi izinto zokugcwalisa zihlanzekile.

8. Umshini usebenzisa isivalo sikazibuthe se-clutch esithuthukisiwe futhi i-torsion torque iyalungiseka, ngakho-ke i-screwing iphephile futhi inokwethenjelwa.

Imikhiqizo Enconyiwe

Okuningi +- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur